We have been covering the joint Fiat Chrysler/Terna/ENGIE V2G project in Milan for the past year or so. Yesterday the first stage of the project was inaugurated during an on site press conference. According to the Terna press release:

Today at the headquarters of the Heritage Hub within FCA’s Mirafiori industrial district in Turin, FCA, Engie Eps and Terna presented the Vehicle-to-grid (V2G) electric-mobility pilot project, which will be the largest in the world once completed.

The V2G installation, located in the Drosso logistics area, was inaugurated during an international conference in the presence of the Minister of Economic Development, Stefano Patuanelli, the Mayor of Turin, Chiara Appendino and the President of the Piedmont region, Alberto Cirio, along with numerous other institutional guests and journalists from Italy and around the world, with a demonstration of its features and operating methods.

The V2G plant at Mirafiori is a project “100% made in Italy”. On the one hand, it is a significant opportunity for the Italian industrial system to take a leading role in the development of the future of sustainable mobility. On the other, it is the result of the joint effort of three companies that lead their sectors. In their use of such an innovative technology, their experiments are now beginning on a bidirectional charging solution that benefits from physical aggregation in a single point of interconnection with the power grid, capable of interacting with the other energy resources on site.

According to the Engie press release:

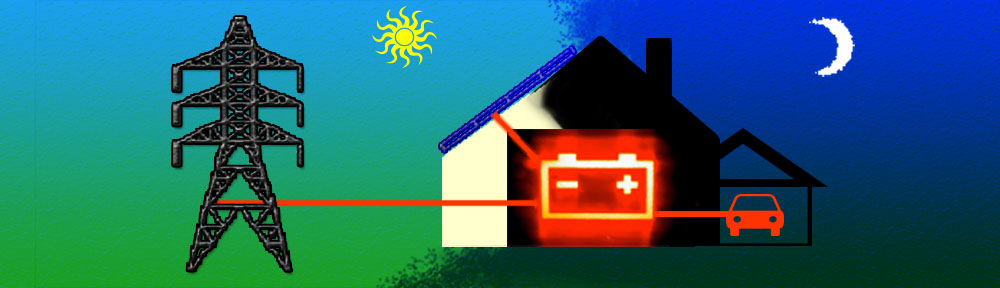

Bidirectional technology – which both charges the car and returns power to the grid – can only work efficiently when the car and the charging infrastructure speak a common language. This is the focus of the trial launched with the inauguration of the plant.

V2G thus represents a major opportunity, which is why FCA – together with its partners ENGIE Eps, the technicians who built the plant, and Terna, the operator of the high- and ultra-high-voltage national power grid – has committed to a cutting-edge project, an example of genuine innovation.

The construction of the plant in just four months, despite the lockdown due to the COVID-19 outbreak, has enabled the transformation of what is typically only a cost (the storage of vehicles waiting to be delivered to the sales network) into a benefit that could be exploited by vehicle fleet managers in the not-too-distant future. Indeed, a (potentially high) number of vehicles parked for long periods in one place represents an opportunity to provide services to the network in an ‘aggregated’ manner.

Here’s a time lapse video of the construction of the pilot site:

According to Terna once again:

Phase 1 of the plant’s construction has consisted of the installation of 32 V2G columns capable of connecting 64 vehicles, aimed at piloting the technology and managing the logistics of the storage area. By the end of 2021, the Drosso V2G project will be extended to interconnect up to 700 electric vehicles, making it the largest facility of its kind ever built in the world. The management of phase 2 will be mainly dictated by cost-effectiveness: the objectives will be to provide services to the Terna power grid and to ensure a positive economic result for FCA and ENGIE Eps.

To cover the parking spaces for the cars connected to the V2G, ENGIE Italia is a partner in the construction of an enormous roof consisting of around 12,000 solar panels, which will supply the production and logistics facilities with ‘green’ energy. The plant will be able to produce over 6,500 MWh of energy every year, resulting in the offsetting of more than 2,100 tons of CO2 emissions per year, a boon for the environment. The project therefore represents a significant contribution to decarbonization in the industrial sector.